With the popularization of gas permeability testing, researches on the relevance of gas barrier property of materials and quality guarantee period of inner products has become more and more intensive. At the same time, how to scientifically and reasonably select packaging materials has also become a new subject. However, because temperature fluctuation of ambient environment affects gas permeability of materials, whether the difference between test condition and actual storage as well as storage environment affects the correct evaluation of gas barrier property of materials attracts much attention. Therefore, effective controlling of temperature and humidity of ambient environment becomes one of the trends in developing gas permeability testers. In this background, this article introduces the influence of humidity on gas barrier property of materials as well as the methods to control humidity of test.

1.The Influence of Humidity on Gas Barrier Property of Materials

Flexible packing materials are made from various kinds of polymers. Some high molecule polymers (such as cellulose, nylon 6, PVA, EVOH) contain hydroxy group-OH and amido –CNH-, etc, which are water sensitive. If the environmental humidity rises, water vapor in the environment will diffuses into polymer materials, as if certain plasticizer is added. This will not only increase the free volume inside polymer, but also facilitate the rearrangement of moving units inside polymer materials. Correspondingly, the number of instant transmission slots for gas molecules are increased, and gas permeability tends to be more. For some other polymer materials containing ester bond –C-O- and cyano-group –C=N, etc., the rising of humidity imposes no influence on the gas barrier property of materials. It can be seen that humidity changes would affect the permeability of some materials, which correlates closely with the polarity and hydrophilic nature of the materials.

To eliminate the above influences, specimens should be regulated under the same conditioning environment before testing. Thus, make the testing data comparable. The status of specimen in GB/T 1038-2000 is required to follow specifications of GB/T 2918 , that is, the specimen should be conditioned in drying container for more than 48 hours or processed according to standard specification of products under 23°C±2°C. In Other gas permeability testing standards, the specimen is also required to take drying process.

2. Humidify Controlling in Gas Permeability Testing

The demand on humidity controlling of test environment is constantly increasing in actual testing. To increase practicality of test data, test data obtained under the same humidity and temperature should be comparable. However, humidity affects barrier property of materials, and in the meantime humidity itself is subject to factors such as temperature. Moreover, humidity controlling can only be realized through direct controlling of test gas. Therefore, humidity controlling in gas permeability testing is more difficult than temperature controlling.

2.1 Humidity Controlling in Gas Permeability Testing of Equal-pressure Method

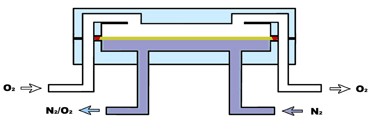

Test principle of equal-pressure method is shown in figure 1 below: permeation cavity is divided into two independent airflow systems by film or sheeting with one side containing the flowing testing gas (pure oxygen gas or mixed gas containing oxygen) and the other side flowing dry carrier gas (nitrogen gas). Pressures on the two sides are equal but oxygen partial pressure is different. Under the function of oxygen concentration difference, oxygen transmits through film and is then diverted into the sensor by nitrogen carrier gas, where oxygen contained in carrier gas is accurately measured by the sensor to calculate oxygen gas transmission rate (O2GTR)of the material.

Figure 1. Test Principle of Equal Pressure method

We can see that in equal pressure method, a continuous gas flow passes through the upper and lower test chambers in the whole process and oxygen partial pressure between the two sides of specimen maintain a dynamic equilibrium, which is unfavorable to the accurate testing of parameters and accurate controlling of equilibrium. However, this is an advantage over humidity controlling of test gas, especially in terms of conveniences of humidity testing and uniformity of humidity. At present, humidifying methods with better application effect are wet and dry gas blending method and mixed pressure method. Precision of these two methods are usually within ±2%RH.

2.2 Humidity Controlling in Gas Permeability Testing of Differential-pressure Method

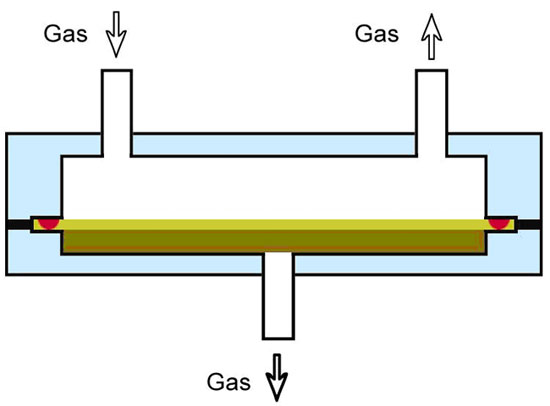

In differential pressure method, (see fig 2), permeation cavity is divided into two independent parts by sample package. Evacuate the two parts, and then fill one side with test gas of 0.1Mpa (absolute pressure) while keep the other side in vacuum state. In this way, a pressure difference of 0.1Mpa forms between two sides of specimen. Test gas transmits through the film into low-pressure side, and then causes a pressure change there. With the pressure variation tested by high precision vacuum gauge, gas permeance can be calculated according to the formula. Differential pressure method can be used to test common inorganic gases such as oxygen gas, nitrogen gas, carbon dioxide gas and air.

Figure 2. Test Principle Of Differential Pressure Method

During the whole testing process of differential-pressure method, the total quantity of test gas inside upper and lower chambers is constant. The pressure difference between two sides of specimen forms a static equilibrium, which is very favorable for the measurement of various test parameters while brings certain difficulty to the humidifying of test gas. Because differential pressure method testing under certain humidity had not been realized in the past, humidity controlling of this method has always been considered impossible. Relying on its rich research experiences of testing instruments and by analyzing the results of various humidifying methods, Labthink combines the saturated saline solution humidity generating method with wet and dry gas blending method, and develops the humidity generating system specifically used for vacuum differential-pressure method gas permeability testers so as to humidify various dry gases to obtain test gases of certain humidity and temperature. At present, this innovative technology can realize humidity generating from 0% to 100%RH.

3. Conclusion

Humidity and temperature controlling is one of the conditions to test gas barrier property of materials in actual application. It provides a test method that can avoid design failure resulting from environment variation. At present, humidity controlling of test gas can be realized through wet and dry gas blending method and mixing pressure method. The SHG-01 humidity generator developed by Labthink is the first to realize humidity controlling of differential-pressure method testing.